Piston vs Screw Compressor: Differences and Factors to Consider When Choosing One

Air compressors are devices with a wide range of applications used across industries, from small DIY projects to large manufacturing plants.

When choosing a compressor, it’s essential to learn about the available types, and usually the choice comes down between a piston compressor and a screw compressor. These two significantly differ in performance, efficiency, and suggested applications.

This article will compare piston and screw compressors and highlight some critical factors when choosing one to help you make an informed compressor choice.

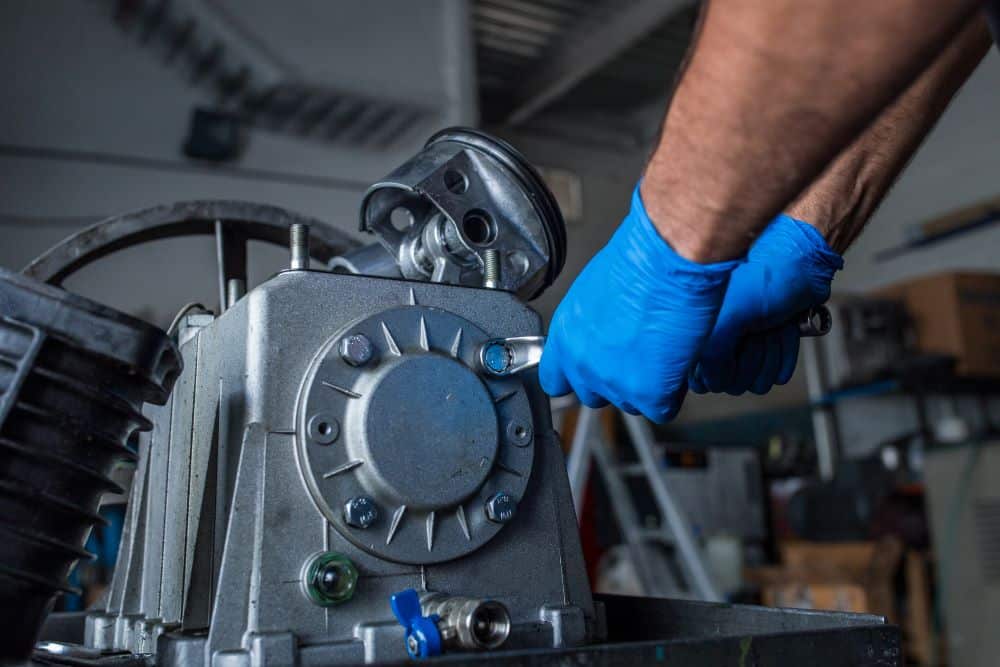

What is a Piston Compressor?

This type of air compressor is the oldest and most used in various industries. A piston compressor compresses air using a crankshaft-driven piston within a cylinder. It increases the air’s pressure by using the principles of displacement.

For the piston compressor to work, it uses its main components, such as piston, cylinder, valves, and crankshaft. This is how it works:

- The piston moves downward and pulls the air into the cylinder.

- The large valve disc then bends downward to allow air to pass.

- The large disc flexes back to seal the valve as the piston moves upward.

- The compressed air is then forced through an opening in the valve and directed until the end process.

A piston compressor is usually found in small workshops, homes, or garages.

Pros

- Lower upfront cost

- Compact and portable

- Recommended for smaller, intermittent tasks

Cons

- Higher noise levels due to its reciprocating motion.

- Frequent maintenance is required.

- If used continuously, some parts might tear easily, affecting efficiency.

What is a Screw Compressor?

This next type of air compressor is also known as the rotary screw compressor and uses a rotary-type positive mechanism to work.

Specifically, this compressor uses two oppositely rotating helical screws to trap the air and compress it as it moves through the chamber. The screw compressor includes various components such as the rotating screws, an inlet valve, and an air or oil separator.

If you need a compressor that can handle continuous air demand, like in industrial or medical settings, screw compressors, especially oil-free screw compressors, are the ideal type for your needs.

Pros

- Lower noise levels due to smooth rotary motion.

- Suitable for continuous, high-demand use.

- Requires less maintenance as it has fewer moving parts.

Cons

- Higher initial investment.

- Larger and less portable than other compressor types.

Piston vs Screw Compressor: Key Differences

Operation and Efficiency

The reciprocating motion of a piston compressor makes it less energy-efficient, especially when used for continuous operation. Meanwhile, screw compressors are known to be more efficient and reliable for heavy-duty applications as it utilises a rotary mechanism.

Size and Portability

When it comes to size and portability, the piston compressor is much smaller and easier to transport compared to a screw compressor which is larger and requires stable placement. The sizes of these two, though, are reasonable for their specific tasks and applications.

Noise Levels

Piston compressors are naturally louder because of their reciprocating movement. On the other hand, screw compressors operate more quietly, making them ideal for environments where noise control is crucial.

Maintenance and Durability

A piston compression contains more moving parts than a screw compressor. Thus, the piston needs more maintenance and frequent servicing over time.

Cost

Due to their capacity, piston compressors are usually more affordable upfront, but if used continuously in heavy tasks, they may incur higher maintenance costs.

It’s different, though, with screw compressors, as they have a higher initial cost, but it can save you money in the long run.

Factors to Consider When Choosing Between Piston and Screw Compressors

Both compressors have pros and cons, so what factors should you consider when purchasing one? The notes below will help you determine which compressor best fits your needs.

Application/Usage

For heavy-duty or industrial use tasks, you may need to opt for screw compressors as they are more efficient and reliable in those types of environments. But, if you need a compressor for home use or small workshops, a piston compressor will do the work efficiently.

Operational Hours

Piston compressors are best used for intermittent, short-burst tasks. So, if your application requires continuous and heavy use, like in manufacturing, it’s best to have a screw compressor.

Energy Efficiency

If you’re in business, your tools and devices must be energy efficient, and typically, screw compressors are the ones that offer better efficiency and lower energy cost. This is what makes them ideal for intensive applications.

Budget

Another essential factor you must consider is your budget, which includes initial and long-term maintenance costs. As previously mentioned, piston compressors cost less upfront, while screw compressors cost higher. However, if they require maintenance in the future, the latter is more economical.

Noise Sensitivity

If you’re in an environment where noise reduction is crucial, you may benefit from getting a screw compressor, as the piston one is louder due to its mechanism.

Space and Portability

A piston compressor is better if you want a compact and portable option, as a screw compressor tends to occupy more space, and it’s better suited in industrial setups.

Maintenance

The maintenance still depends on how you use the device. However, usually, screw compressors require less frequent maintenance than piston compressors.

Choosing the Right Compressor for Your Needs

Assessing your unique requirements is still the best way to come up with a decision on what’s better between a piston compressor and a screw compressor. These two air compressors have qualities and functions that are unique to them.

After you weigh and consider all the factors mentioned above and still have questions, don’t hesitate to contact a trusted air compressor servicing in Singapore, like Lian Beng Machinery Co.

We deliver various top-notch air compressors, such as piston compressors and oil-free screw compressors. All our products are exported worldwide and meet industry standards, codes, and certifications.

Contact us to learn more!